Beryllium copper is a copper alloy containing 0.5 to 3% Beryllium. It can also contain some lead to improve machinability. Most used beryllium copper alloys are CuBe2 | C17200, CuBe2Pb | C17300 and CuBe1,7 | C17000.

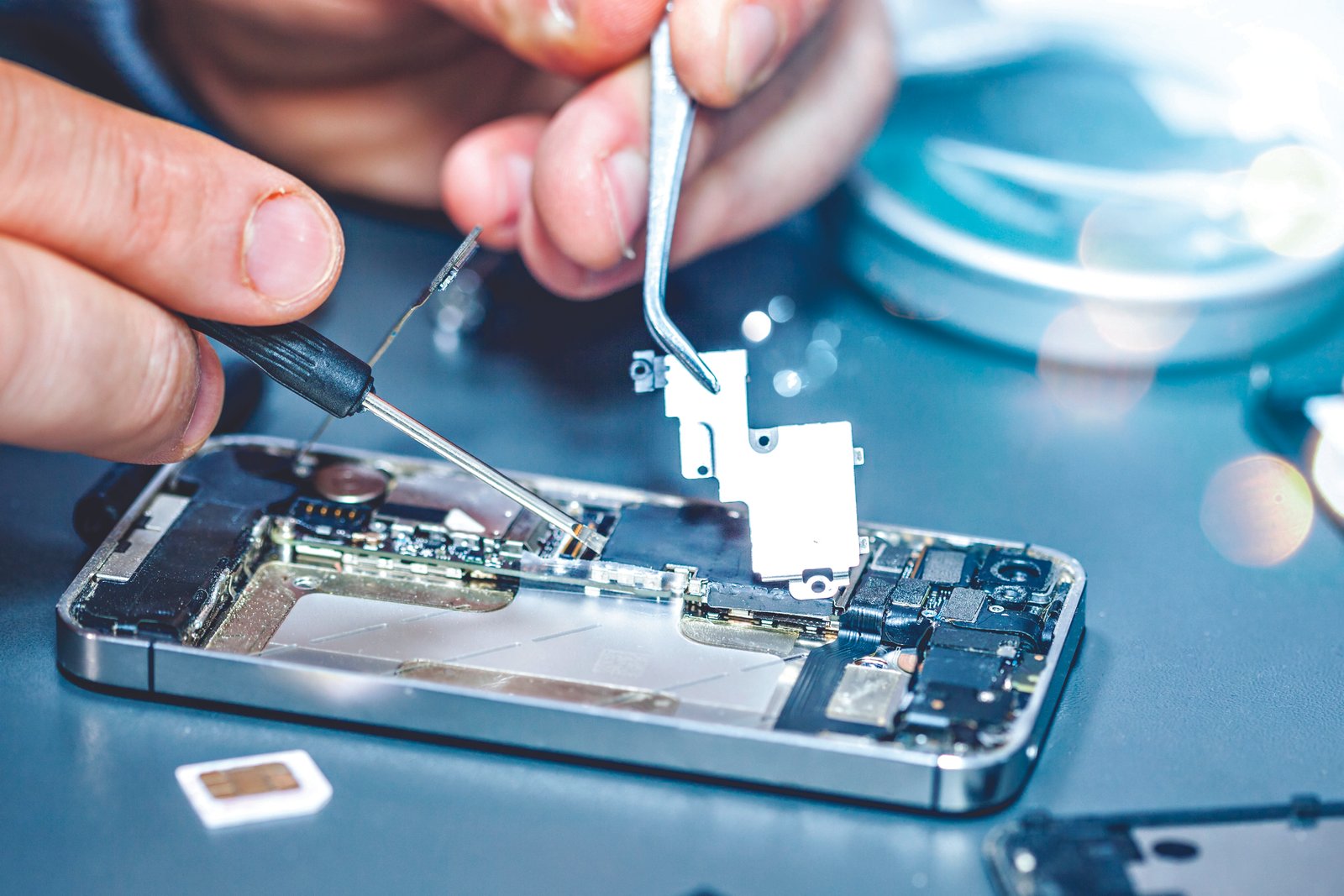

Thanks to its great compromise between conductivity, mechanical properties it has been widely used in rolled and wire formats. Therefore, we find this alloy in connectors, plastic molds, cryogenics parts and musical instruments among various applications.

Nonetheless, beryllium copper has been determined to be toxic: breathing beryllium particles can cause lung disease and is not in compliance with REACH regulations. That’s why manufacturers in various industries are switching to beryllium free alternatives.

Lebronze alloys solution : Niclafor® 1000| CuNi9Sn6 | C72700

For this purpose, Lebronze alloys developed Niclafor® 1000 |CuNi9Sn6 | C72700, a lead and beryllium-free spinodal alloy composed only of copper, nickel and tin : an excellent substitute for beryllium copper.

Niclafor® 1000 |CuNi9Sn6 | C72700 exhibits very high mechanical properties, such as Tensile Strength and Yield Strength above 1,000 MPa (145 ksi) depending on temper, even at high temperatures.

Niclafor® 1000 |CuNi9Sn6 | C72700 is strictly amagnetic, it has a good corrosion resistance and non-sparkling on impact.

Niclafor® 1000 |CuNi9Sn6 | C72700 has also an excellent fatigue resistance and low friction. It also exhibits high elasticity and formability allowing light and durable designs.

Thanks to its physical properties and composition Niclafor® 1000 |CuNi9Sn6 |C72700 is a safe and environmentally friendly alloy that complies with REACH and RoHS regulations ensuring a high level of protection of human health and the environment against chemical risks and making it a good alternative to beryllium copper. Indeed, tests are carried out by independent expert laboratories and/or declarations showing that the parts comply with both legislations.